Refinishing Cockpit Tables

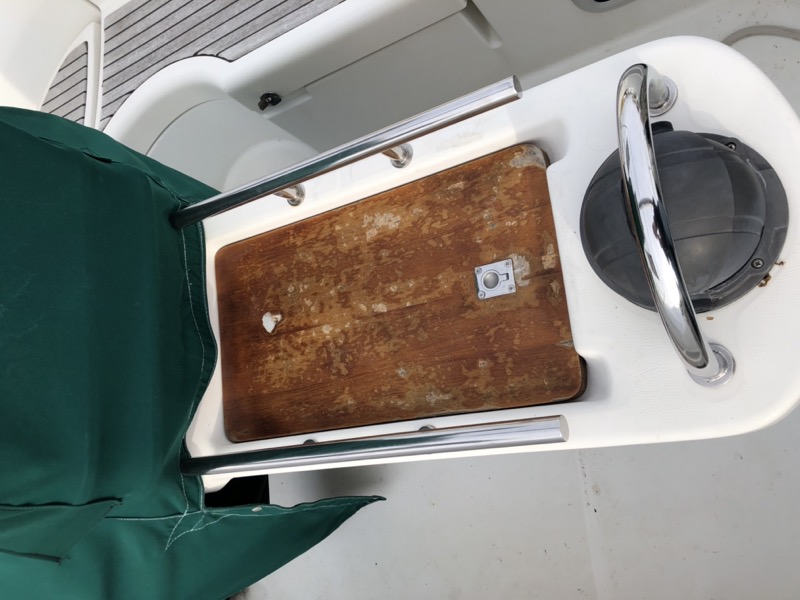

A client and good friend asked me to refinish these drop-leaf cockpit tables for their Beneteau 400. This was a nice project to do over the off-season when it’s usually too cold to work outside.

Varnished brightwork can look fantastic, but requires diligent maintenance to keep it in good shape, typically 2-3 maintenance coats per year for one-part varnishes. Like many boat owners, these clients didn’t want to spend nice summer days varnishing when they could be sailing. So in addition to get the tabletops back in shape I wanted to set them up with a low-effort way to keep them looking good in the years to come.

The first step was to remove the old, chipped varnish. Initially, I wasn’t sure if the teak and holly surface was a veneer, so I wanted to avoid sanding. Instead I removed the old finish with a heat gun and scraper.

Once I got down to bare wood it appeared that the center section had been damaged by some sort of oil (food, engine lubricant, who knows) that left a dark, spotted stain beneath the varnish. Fortunately, an application of oxalic acid dissolved in water removed the stain almost completely.

Once the tops were fully scraped, cleaned and lightly sanded, I applied my “go to” one-part varnish: Epifanes clear. Epifanes is not the easiest choice for maintenance coats (more on that in a bit), but it provides a warm, durable, high-gloss finish that levels out nicely. I thinned the first 3 coats as instructed to seal the wood and applied 4 additional full-strength top coats.

The clients preferred a satin finish instead of the high-gloss Epifanes, and they were looking for something that would be easy to maintain during season. I had been experimenting with a water-based varnish from Jamestown Distributors called Halcyon, available in both gloss and satin finishes. Halcyon dries quickly (about an hour at 72° F) and you can overcoat without sanding. Jamestown claims you can apply up to 5 coats per day. By comparison, Epifanes requires 24 hours between coats with sanding in between. Additionally, Halcyon comes in an innovative tetrapak container. In theory, this reduces waste by letting you pour out just what you need, then squeeze the air out so that the varnish in the package doesn’t skin over. One of my pet peeves is that the last third of a can of varnish seems to always spoil in the can, so this is a nice feature. I wish all varnishes came this way.

I decided to apply 2 final coats of Halcyon Satin to provide the desired finish and set up the owners with a low-maintenance option. My theory here is that reducing the tedium of varnish maintenance makes it less likely that boat owners will put it off until it’s too late. And laying down 2-3 seasonal coats in a single afternoon is a lot easier than having to do that same work over 3 days with sanding in between.

Here are the finished sections installed back in the cockpit.

Important Postscript

A comprehensive varnish comparison I did during the 2022 season showed that Halcyon provides surprisingly poor UV protection over time. Fortunately there are one-part polyeurethane alternatives (including Gleam and Lust) that so far provide very good UV protection, dry nearly as quickly, and allow multiple coats per day without sanding. I’ve recommended the client switch to Gleam 2.0 for maintenance coats. The only downside is that Gleam and Lust don’t come in tetrapak containers.