Select Projects

Hull repaint

The existing Awlgrip paint job was at least 25 years old and failing in several spots, exposing the original gelcoat beneath. I sanded the hull back to gelcoat, filled several dozen holes and other imperfections, faired, primed, and painted with Alexseal (rolling only, no tipping). I’m still working on the boot and cove stripes. Read more.

Replacement hatch cover

A brief attempt to repair a shaky hatch cover soon turned into a full replacement using fiberglass and a custom mold. Major challenges included getting the dimensions just right and ensuring that the hatch opened smoothly and closed snugly. Read more.

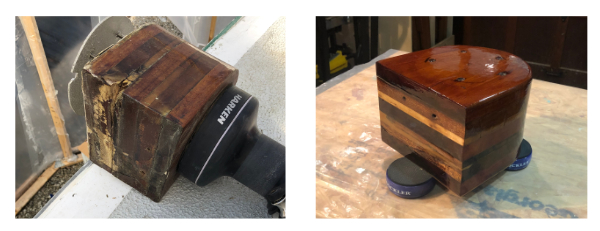

Winch block refurbishing

This project is part of a larger plan to refurbish the coamings and other brightwork in the cockpit. When we disassembled the coamings I discovered significant rot in one of the jib winch blocks. After sanding off the old varnish I used penetrating epoxy to repair the rot, reinforce other weak spots in both blocks, and faired the bases to mate perfectly with the deck. Then I sealed the winch blocks with epoxy and applied multiple coats of varnish. Read more.

Custom instrument panel

This project replaces an OEM plastic instrument panel mounted on aging plywood with one made of new mahogany plywood within an inset mahogany frame. I also wanted to replace some unused instruments, untangle a few decades worth of convoluted wiring, and–literally–add a few new bells and whistles. The new setup also includes a properly wired engine alarm with the instrument circuits wired through a bus bar for simplicity and an extra switch to toggle the backlight on the cockpit compass. The plywood and frame are sealed with clear epoxy and varnished. Not shown is a wrap-around mahogany cover held in place with magnets that attach to the brass rivets.

Sea Sprite makeover

![]()

Some projects aren’t especially complicated. What this charming 1980’s Sea Sprite needed most was a really good scrubbing, followed by a teak sealant to restore its former shine. Read more

Distribution panel replacement

The circuits, distribution panel and instrumentation on this Catalina 25 weren’t working reliably and were riddled with safety concerns. I replaced the existing AGC fuse-based panel with a circuit breaker panel, installed a battery monitor, speed and depth gauge, and fabricated mounting panels for the new equipment. Read more