Upgraded Distribution Panel and Instruments

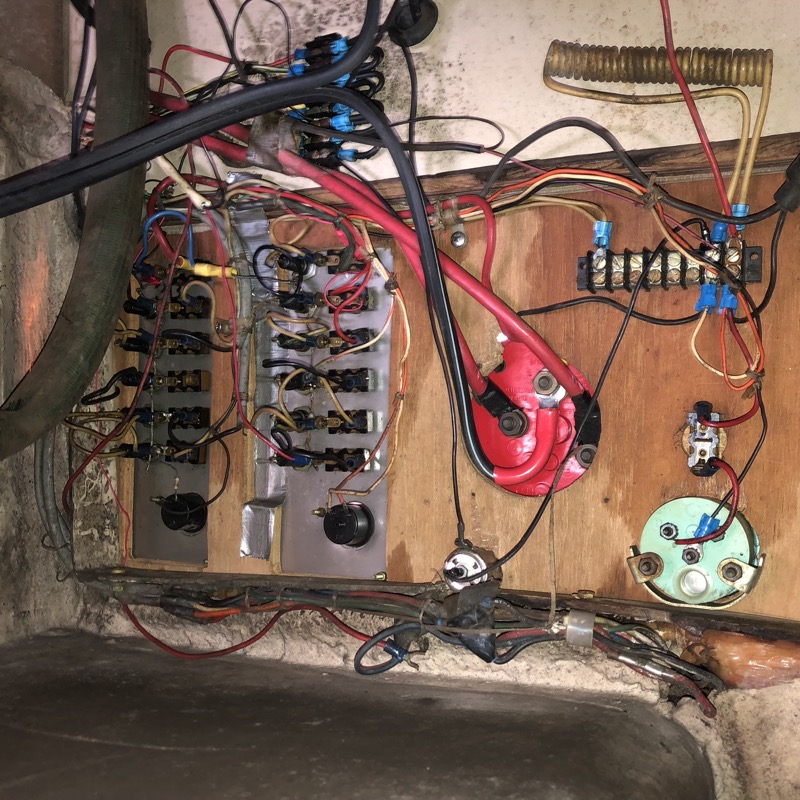

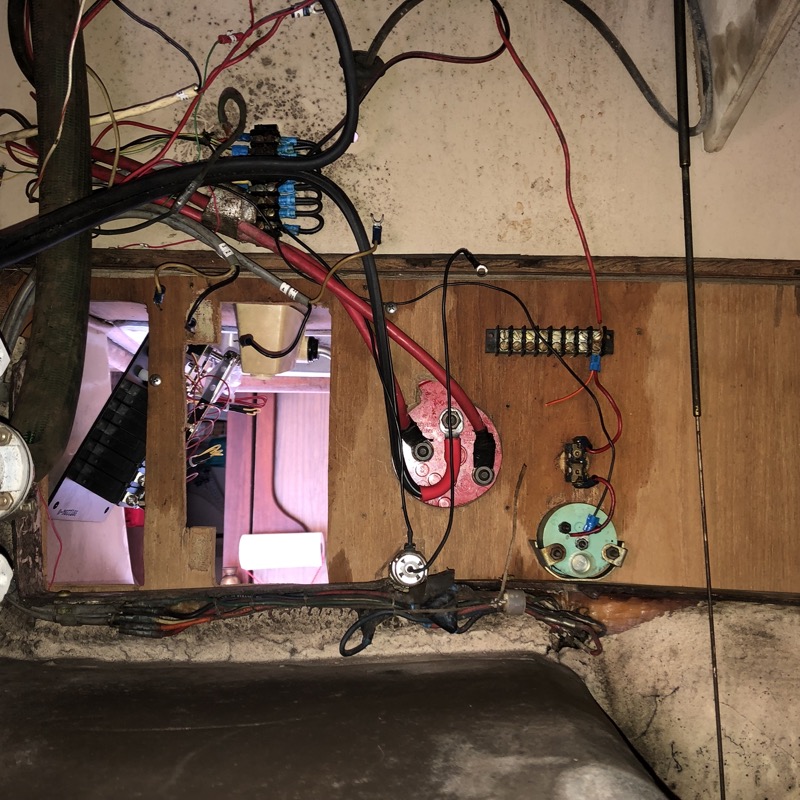

This was a fun project involving electricial systems and a bit of carpentry. The owner has a Catalina 25 in which the original distribution panel had been replaced at some point with an expanded version that looked like it had been built from scratch. He complained that circuits were failing one-by-one and it wasn’t clear where the issues lay. The instruments and cockpit gauges had long since stopped working and most of the instrument wires had been cut.

At a minimum, he wanted essential systems (cockpit and navigation lights, VHF, etc) to work again, and if possible to replace the cockpit instruments with modern, functioning equipment.

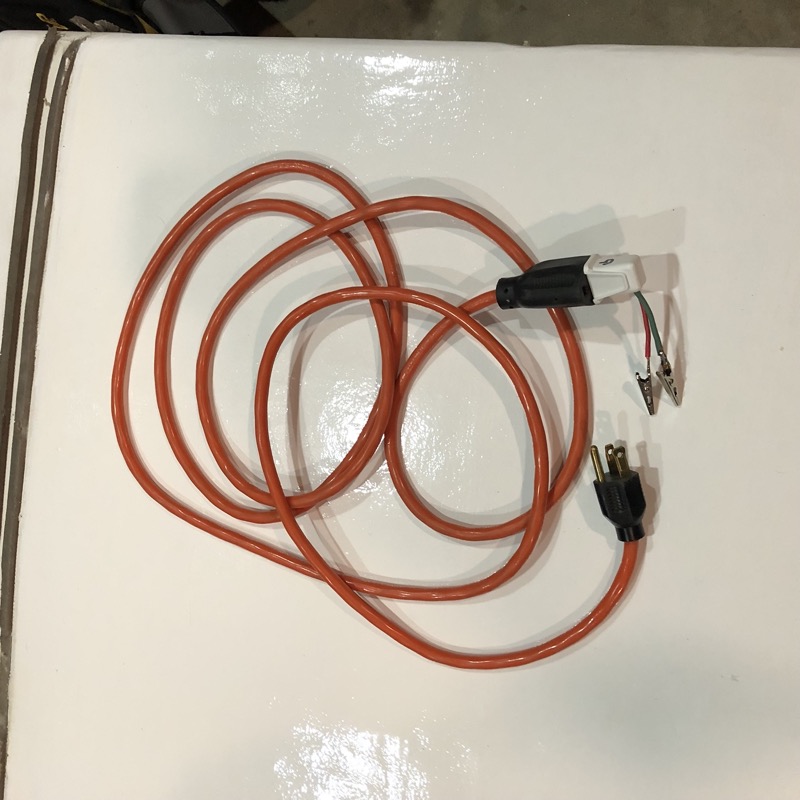

My first step was to do a deep-dive on the existing installation to identify which circuits actually worked along with causes of failure. This meant a lot of continuity tests with a voltage meter. For this work I bring along a long extension cord with an adapter that helps me test both ends of a circuit that might be 20 feet or more apart.

It turned out that several circuits either had blown fuses or were simply mis-labeled on the panel, and might have been easily fixed. Fortunately, much of the circuit wiring itself was intact and could be kept. However, a look at the back of the panel raised more significant concerns. It featured not only the typical mix of inefficient and confusing wiring, “dead end” connections etc, but the panel itself was constructed through uninsulated soldered connections. A major safety issue!

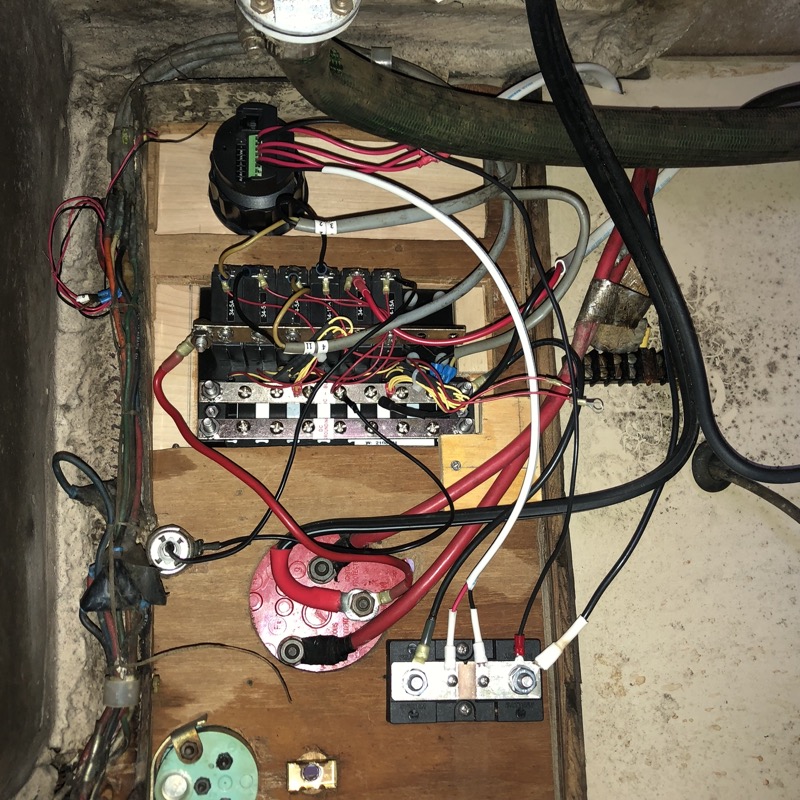

I recommended the distribution panel be replaced with a more robust alternative; a Paneltronics DC circuit breaker panel with room for up to 8 circuits that would be more reliable than AGC fuses. In addition, we selected a new depth meter and GPS-based speed gauge to replace the non-functioning instruments in the cockpit, and I updated the circuit layout to reflect the new instruments and eliminate unused systems (like the AM radio). The owner also wanted a better way to monitor his engine and house batteries, so I added a Xantrex Battery Monitor to the plan.

Then I set about removing the old distribution panel along with all the obsolete and disconnected wiring.

The new distribution panel and battery monitor fit the existing space quite nicely in terms of ergonomics, but would have left open holes where the old panel had been. So I made a simple mounting panel that would accommodate the new equipment and cover the old space. When possible, I first make a template from scrap plywood before cutting the final piece from mahogany or whatever I’m using.

After completing the mounting panel, I installed the new distribution panel and battery monitor, ran new wire where required and reused existing wire where possible.

In the cockpit, removing the existing instrument gauges left similar openings in the side of the cabin, so I made another mounting panel for the new instruments out of King Starboard.

On the cabin side, I temporarily taped the GPS antenna in place so the owner could test the upgrades on the water.

Once we confirmed the GPS antenna would work when mounted within the cabin, I afixed it to the inside of the starboard panel and created a cover to keep the wiring out of sight: a nice upgrade from the previous setup.